Solutions

PRASA’s Cooling Technology Solutions

Pioneering Efficiency with RDHx, DCLC and LIC Cooling Solutions

SUSTAINABLE DC COOLING SOLUTION

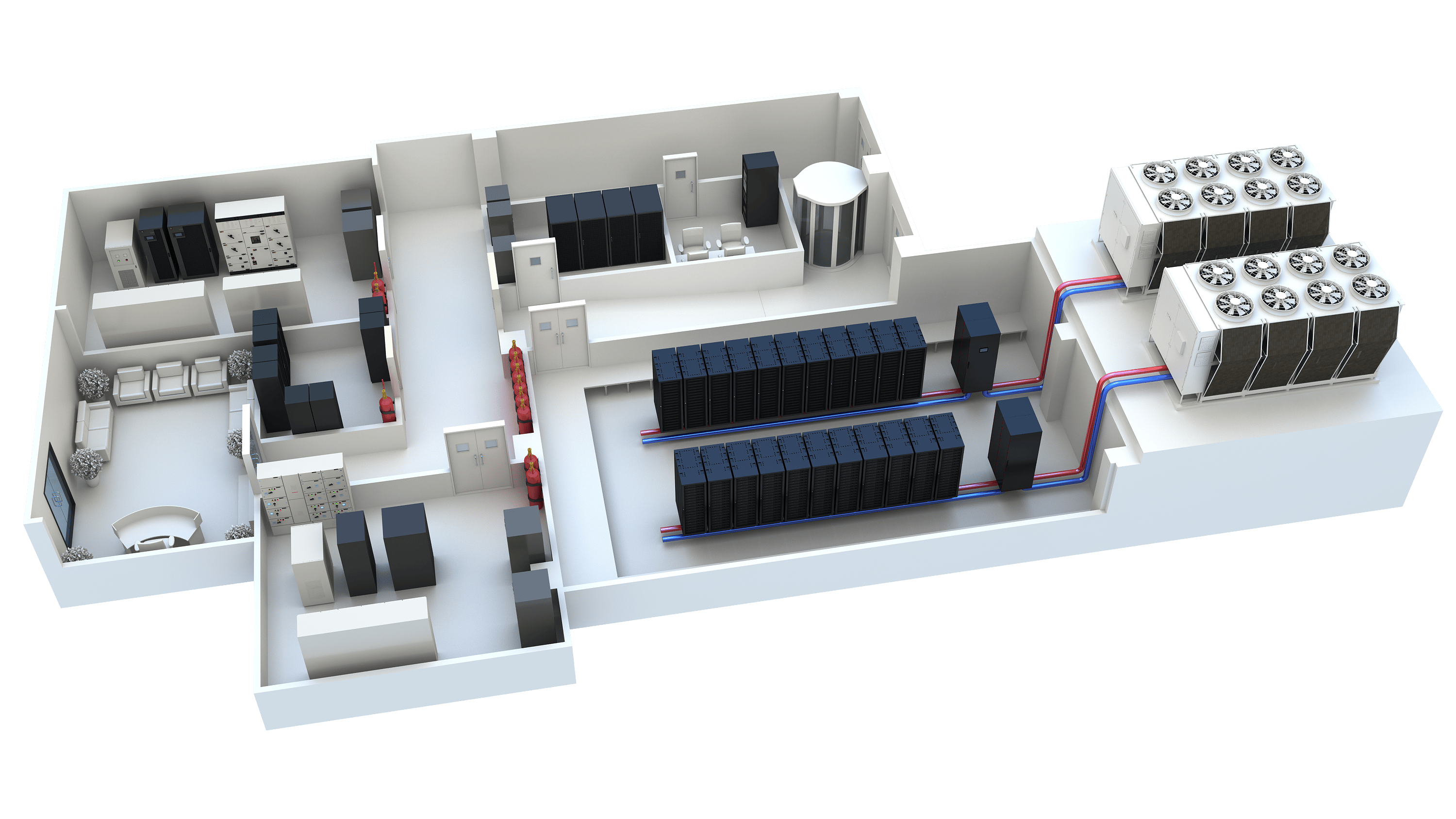

RDHX (Rear Door Heat Exchanger Solutions)

Rear Door Heat Exchangers (RDHx), is the most effective air cooling technology in high-density environments. It can cool up to 74 KW of heat load inside a single 52U rack.

RDHx systems work by removing heat from the exhaust air of IT equipment through a heat exchanger mounted on the back of the server rack. In this process, chilled water (the “liquid” component) absorbs heat from the exhaust air, cooling it before recirculating it back into the data center.

- HEAT LOAD:

RDHx is most effective in high-density environments with substantial heat loads, providing efficient cooling directly at the equipment level.

- SERVER DESIGN:

RDHx suits any of the shelf air-cooled servers with the latest CPU/GPU processors.

PRASA has successfully implemented over 4-5 MW of RDHx cooling capacity, showcasing its commitment to innovative, efficient data center cooling solutions. With Power Usage Effectiveness (PUE) values between 1.35 – 1.4, PRASA’s RDHx deployments have demonstrated significant energy savings and optimized performance for data centers. Contact us today to learn how PRASA can elevate your data center’s efficiency with cutting-edge cooling solutions.

PRASA EXPERTISE:

PRASA’s ability and experience to select and integrate the right product portfolio to achieve high-density cooling mechanisms using air as a medium has been the best in the industry. PRASA takes complete end-to-end responsibility for picking the right product to integrate with the rack suitable for the deployed compute inside the rack to give a seamless experience for the customer.

PRASA undertakes the responsibility of:

• The right Selection, Supply, Installation, and commissioning of chiller as per the ambient temperature.

SUSTAINABLE DC COOLING SOLUTION

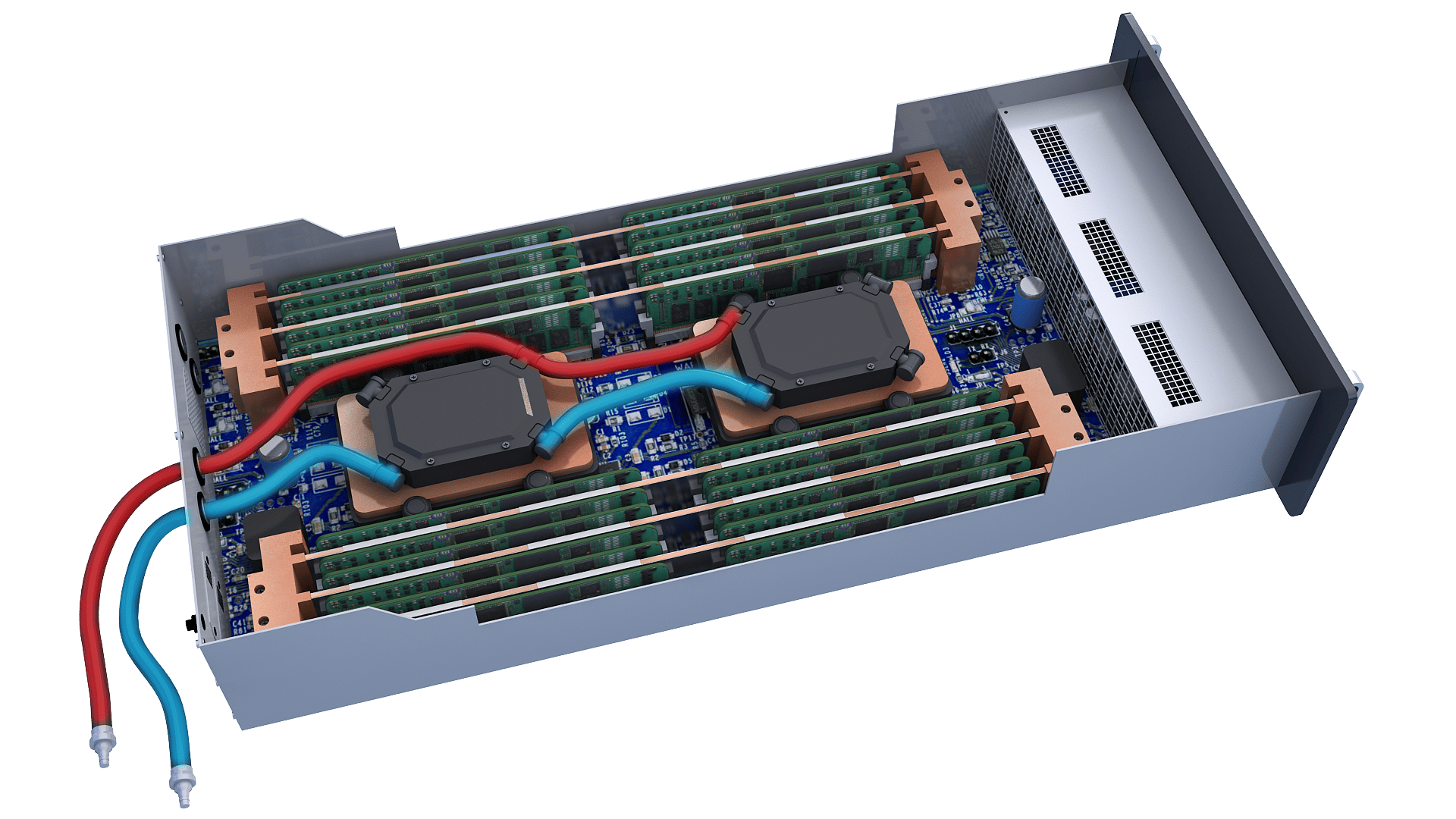

DCLC (Direct Contact Liquid Cooling)

Direct Contact Liquid Cooling (DCLC) represents a leap in efficiency and performance for high-density data centers. Also known as Liquid-to-Liquid Cooling, DCLC operates by channeling coolant directly over server components, such as CPUs, GPUs, and memory, effectively managing temperatures while supporting heat loads up to 80kW per rack.

PRASA has successfully implemented this technology for nearly 2 MW of IT load, operating efficiently for several years.

WHY DCLC?

DCLC minimizes environmental impact and reduces operational costs. Heat is transferred away from critical components and dissipated through an integrated heat exchanger, achieving Power Usage effectiveness (PUE) ratings between 1.2 to 1.3. DCLC systems are optimal for scalable deployments, providing unmatched thermal

control even in demanding climates and environments.

DCLC System Types:

SINGLE-PHASE DCLC:

Single-phase Direct Contact Liquid Cooling (DCLC) utilizes a two-liquid system to manage heat. The primary liquid in this setup is warm water, which absorbs heat directly from the server components. The secondary liquid is a mixture of water and glycol, which acts as a coolant to transfer the absorbed heat away from the IT hardware.

TWO-PHASE DCLC:

Two-phase Direct Contact Liquid Cooling (DCLC) is an advanced thermal management system that uses two distinct liquids to enhance cooling efficiency. The primary liquid in this system is warm water, which absorbs heat from the IT components. The secondary liquid is a synthetic dielectric liquid, which is engineered to facilitate heat absorption and ensure a more efficient phase-change process.

Types of

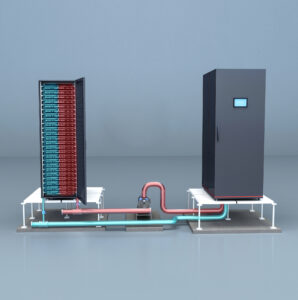

Coolant Distribution Units (CDU):

Coolant Distribution Units (CDUs) are critical in maintaining optimal temperature control within data centers, ensuring that servers and IT equipment operate at peak efficiency. Various types of CDUs are available to meet the specific cooling needs and configurations of data centers. These include In-Row or Sidecar, In-Rack, Liquid-to-Air (L2A), and Liquid-to-Liquid (L2L) CDUs, each designed with unique features and tailored to specific cooling requirements.

Liquid to Air (L2A) CDUs:

Liquid-to-Air (L2A) Coolant Distribution Units (CDUs) efficiently transfer heat from a liquid coolant, such as water or a water-glycol mixture, to the surrounding air.

Liquid to Liquid (L2L) CDUs:

Liquid-to-liquid (L2L) Coolant Distribution Units (CDUs) transfer heat between two distinct liquid cooling loops, with facility water used to extract heat from the equipment in server racks and rows.

SUSTAINABLE DC COOLING SOLUTION

LIC (Liquid Immersion Cooling)

GRC Delivers Game-Changing Cooling

Business success today is increasingly tied to IT. Yet traditional data centers are facing a host of challenges. For one, they are very costly to build & difficult to support in harsh environments. What’s more, amid soaring demand for greater computing capabilities, server heat dissipation has become a huge barrier, as have rising power costs.

Redefining the efficiency and Sustainability of Data Center Cooling Micro-Modular, Rack-Based Immersion Cooling Systems for Enterprise Data Centers:

- Increases cooling performance up to an amazing 368 kW*

- Cuts cooling energy by up to 95%

- Reduces TCO up to 44%

- Delivers an outstanding mPUE of <1.03

- Conserves water and power – Be Greener!

- Decreases compute footprint dramatically

- Works with all major OEM servers

Liquid Cooling for AI Workloads

In today’s dynamic technological landscape, artificial intelligence (AI) is catalyzing an unprecedented demand for high-performance computing (HPC) solutions. The rapid adoption of AI applications, powered by advanced machine learning (ML) and deep learning algorithms necessitates significant computational resources to process vast datasets and execute complex operations. This computational intensity, while critical for innovation, generates substantial heat within data center environments, posing challenges to traditional cooling systems.

Conventional air-cooled systems often fall short of addressing the high heat density produced by AI-driven

workloads. As a result, forward-thinking organizations are turning to innovative liquid cooling technologies to

meet these demands effectively. Liquid cooling solutions utilize advanced methods such as submerging

hardware components in dielectric fluids or delivering targeted coolants directly to heat-intensive components. These approaches not only enhance heat dissipation but also improve overall system performance, energy efficiency, and reliability.

At PRASA, we are at the forefront of delivering state-of-the-art cooling technologies tailored to meet the demands of AI and HPC environments.

Our portfolio includes: RDHx, Direct Contact Liquid Cooling (DCLC), and Liquid Immersion Cooling (LIC)

These innovative solutions are designed to meet the growing computational and thermal demands of AI workloads; ensuring data centers achieve peak performance and reliability while maintaining energy

efficiency and sustainability. With PRASA’s expertise, businesses can embrace AI-driven growth confidently, knowing their critical infrastructure is supported by advanced, reliable cooling systems.