Prasa Infocom blog has started a series of posts to examine the role of edge data centers in different industry verticals. We will cover how the edge will handle the growing demand from various sectors. We have already covered healthcare, now we are talking about Manufacturing and industrials.

Edge computing is swiftly making its way into multiple industries as IoT (Internet of Things) devices become omnipresent. One of the most impressive growths for IoT is currently seen and is also projected to come from the industrial and manufacturing sectors. Industrial Internet of Things (IIoT) encompasses various technologies, which facilitate the functioning of industries and manufacturing processes. It is also the biggest contributor in the next industrial revolution-Industry 4.0. In 2017, the global IIoT market size was USD 2.57 billion, which is expected to reach USD 13.82 billion by 2023, growing at a CAGR of 33.4% during this period.

The average age of factories in the US is 25 years, which are equipped with machinery that is almost 10 years old, with companies looking to invest in, and upgrade to a new generation of smart machinery, IIoT powered by the edge is beginning to take over the traditional operations and systems.

Manufacturers and Industries have always produced huge data, via their control systems and drive systems, but due to lack of integration between the data sources, the data was never fully harnessed. The IIoT now makes this possible and drives the industries towards accelerated growth and modified economics. Manufacturers and industries now ensure more efficiency in all aspects with the integration of IIoT, from operations and services to engineering and product.

The consumers are embracing IoT with open arms, but the industry is a step ahead and is under complete revolution with Industrial IoT. IIoT is affecting all layers of industrial hardware and software creating factories of the future. Consider an equipment that will give advance notification about its imminent breakdown; intelligent factory floors that are connected to a server to obtain the status of raw material progress and assembly line production in real-time; smart glasses that let the field technicians work hands-free when remote supervisors are walking them through the solution.

IIoT also ensures increased customer satisfaction, as it allows asset tracking through the supply chain, capturing and analyzing data about the usage of products, paving a way to build roadmaps for more customer-centric and futuristic products.

IIoT is turning out to be the lynchpin in Industry 4.0, which applies to manufacturing and smart factories, connectivity which serves as the physical building block of IoT as well as IIoT. It comprises of device sensors and processors which generate data and execute the decisions made by the software.

IIoT with its multiple benefits like- asset optimization, smart monitoring, predictive maintenance and intelligent decision making is no longer “an upcoming technology”; we are very well into the age of IIoT.

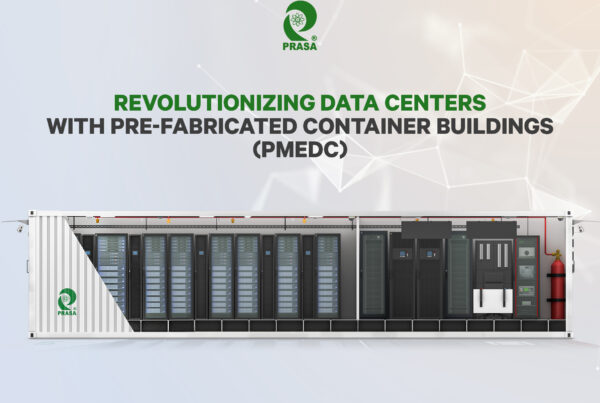

IIoT revolutionizes the manufacturing and industry sector and creates a huge amount of data at the site which needs to be processed and stored. Now if we look beyond latency and bandwidth, transferring this massive amount of data across states and countries to the central data center is neither secure nor cost-effective. Edge computing has brought in the concept of micro data centers and containerized data centers which process the data on-site, making the working of these systems faster, cheaper, and safer.

Containerized Data Centers are the demand of the sector with IIoT and edge. The make sure data security is pivotal and meets the urgency for handling critical data on-site and quickly. Containerized data centers keep the data at the industry premises or nearby for immediate use, without having to depend on a network, also unlike traditional data centers they need very little to no space, and consume very less power, making them environment-friendly. They are also very quick and easy to deploy.

If you want to know more about how a data center is a mission-critical infrastructure in meeting the rising edge requirements of the manufacturing sector, or how having your own data center will facilitate the functioning of your industry, you can contact our experts at Prasa Infocom & Power Solutions Pvt. Ltd. We have been associated with the big names in this sector for some time now.

Stay tuned for the next post in this segment that will cover the role of Edge Computing in the ‘Banking sector’

References

https://internetofthingsagenda.techtarget.com/definition/Industrial-Internet-of-Things-IIoT

https://www.marketsandmarkets.com/Market-Reports/industrial-iot-platform-market-11186318.html

https://www.vxchnge.com/blog/edge-computing-use-cases-manufacturing